What we have to Offer

A wide range of materials and constructions with high-quality elastomers EPDM, SILICONE and FLUORO ELASTOMER and FLUORO PLASTICS (PTFE) – used independently or combined with woven glass or ceramic fabrics and insulating materials.

Our Team

A team of experienced sales engineers are freely available, without obligation, to discuss customers individual requirements and to design the most cost-effective solution to the problem.

What Sets Flextra Apart

FEP uses woven fabrics rather than metals to provide a flexible element in an expansion joint. This well-established practice allows the designer much greater freedom in space and movement capability than comparable metallic expansion joints and their freedom to move in all planes minimizes duct lengths and greatly simplifies support systems. Elastomeric or Fluoroplastic outer covers provide the necessary gas seal.

Flextra specializes in the design development and manufacture of fabric expansion joints to allow for:

- Thermal expansion in ducts and chimney flues

- Vibration isolation of fans or machinery

- Isolation of components for maintenance or fire risks Each unit is designed and manufactured to ensure complete compliance with customers specifications and requirements.

Typical applications are in:

- Power Station flue ducts

- Gas turbine exhausts

- Boiler penetrations

- Industrial furnace off-gas ducts

- Sugar mill boiler ducts

- Smelter off-gas ducts

- Cement works

- Drying plants

Flextra is a business built around more than 50 years experience in design, manufacturing and installation of high-quality thermal insulation products in a range of applications both in South Africa and other countries on the continent. Using the highest quality products from international suppliers the team creates custom designed products for any requirement from simple tapes, ropes and cladding to fabric and rubber expansion joints.

Unique products can also be tailor-made to meet any need in any industry. The manufacturing environment is kept manufactured to quality standards to ensure each and every product is manufactured to exact specifications.

Our BBBEE credentials are aligned to ensuring all our staff benefit from the success of the business by ensuring ownership opportunities to staff at all levels of the organisation. This linked to our focus on job creation, by using local fitters and installers, rounds off Flextra’s overall commitment to upliftment and job creation in South Africa.

Why Choose Flextra

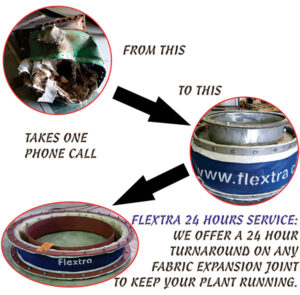

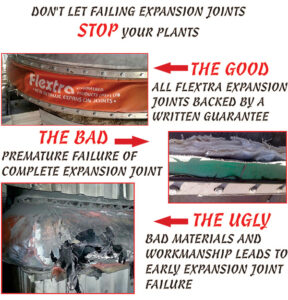

At Flextra we have the expertise and products to provide a solution to any expansion joint problem be it temperature, pressure, corrosion or a combination of all operating conditions. We do not provide an expansion joint that will fail permanently and guarantee all our products.